Automate The Process:

Reducing front-end expenses and increasing quality and efficiency has always been a top priority for producers, highlighting the need for companies to thoroughly evaluate their current methods of reducing waste – wasted efforts, wasted energy and wasted product. Evaluating and implementing lean manufacturing principles assists in eliminating waste and improving overall plant production. With the implementation of moisture control systems, manufacturing plants can save a large amount of money in a short amount of time.

When considering the many challenges that plant operators are tasked with, moisture control plays a large role. Moisture content can affect product quality and equipment function, making it a crucial focus point in proactive avoidance of quality control issues. Dryer effectiveness is critical, as dryers consume a large amount of energy during operation. The implementation of moisture measurement before and after the dryer provides immediate control over the temperature and operational efficiency.

Reliable, Repeatable Results

Moisture measurement and control sensors are located in countless applications all over the world, saving manufacturers time and money by quickly detecting the variable manufacturing process, allowing corrections to be made in real time. Near-infrared (NIR) technology is best suited for instant online, offline and laboratory moisture instrumentation. Controlling moisture levels in powdered and granular applications production is a critical process during various stages of production, as the product can easily become too wet or dry, causing immediate production and quality issues.

Bottom Line Benefits

The ability to reduce waste and keep the production line moving is essential to plant operators. Moisture measurement and control plays a large role in the process and catching out of tolerance readings as quickly as possible on the line allows for increased plant efficiency and product quality.

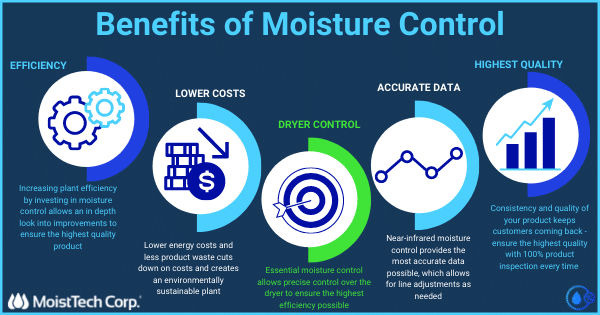

Real-time process control with moisture detection provides true product data that can be used to improve operation efficiency. This reduces wasted effort and materials, and decreases the frequency of downtime, manual intervention and defective goods. Increased plant efficiency, lower energy costs, higher accuracy, instant return on investment (ROI) and low to zero maintenance are just a handful of benefits seen when implementing a moisture control system.

Optimizing the manufacturing process to include a moisture measurement and control system improves product quality and production efficiency and reduces the amount of dust and build-up created. Small variations in moisture content can result in clumping, affecting the quality and consistencies in the production; absence of moisture can result in excess dust. Non-contact moisture detection can provide real-time accurate data to help line personnel to properly control and eliminate common issues.

.

Moisture Measurement Systems Alleviate Human Error

Manufacturers can experience immediate adjustments to their process based on real-time measurements, as the sensor reads and records hundreds of data points per second. Immediate changes can be made to the production line directly through the programmable logic controller (PLC) needed, to stop extra waste and maintain the effective movement of production lines. Additionally, costly downtime and excessive waste is avoided by catching any out-of-tolerance readings as quickly as possible. Manufacturers can connect the sensors to a computer network or production laptop for complete software control of the production line, creating a closed loop process

Do you have a question about our moisture control products or how MoistTech can benefit your production line? Learn more here, or feel free to contact us today with any questions you may have or to request a free quote. We look forward to hearing from you!