online near-infrared

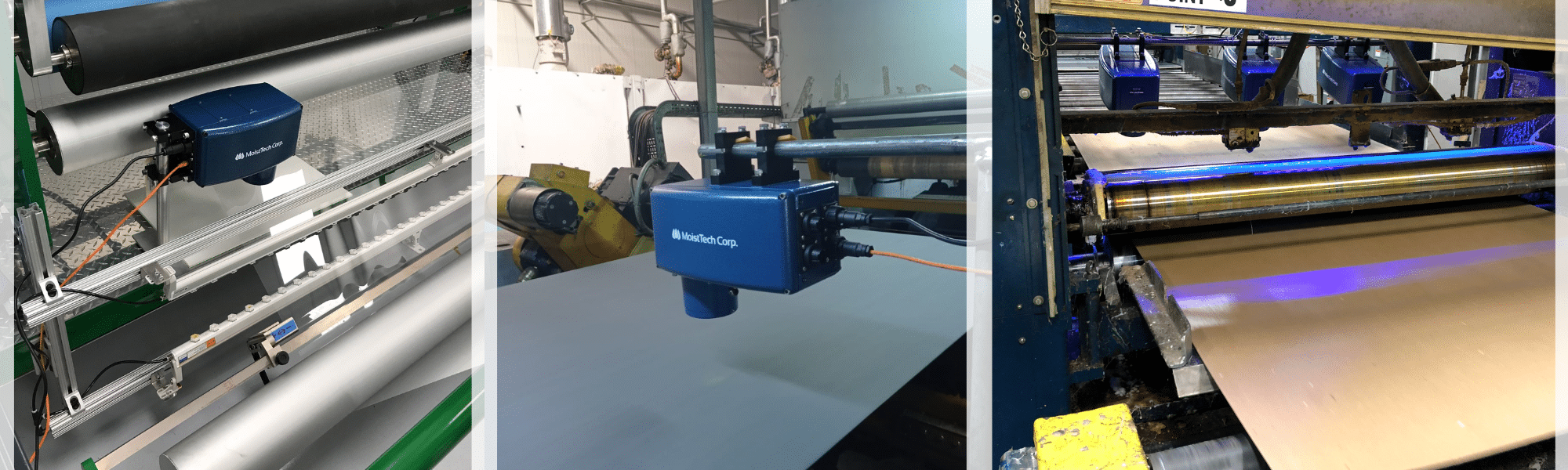

ir-3000C: Converting Products

proper moisture measurement & control in Coat Weight, Thickness

Manufacturing any product requires producers to focus on minimizing waste, reducing costs, continually increasing product quality and maximizing overall plant efficiency. In converting applications other factors like Coat Weight, Thickness and moisture can play a large role in maintaining the efficiency of the plant. Creating the need to evaluate and implement lean manufacturing practices to identify the key areas in which the manufacturing process is not operating at its peak ability.

MoistTech produced the IR3000C sensor to precisely measure moisture, coat weight, thickness, moisture or temperature in converting applications such as paper, films, foils, composite board, hot melts, glues, recycled paper, wax and vinyl coating, resin and many more.

Thoroughly evaluating methods of reducing wasted product, efforts, time and energy will provide the needed efficiency to increase plant productions. Above all, proper coat weight, thickness, moisture measurement and control can play a large role in the overall converting production process and quality of the product. Implementing a moisture management system is low cost and provides instant ROI.

Efficiency is Key

Often efficiency in the converting production process is affected by variations in coat weight, inefficient moisture control, thickness and/or temperature issues. Moisture and thickness play a large role in the final product quality and use.

Certainly precise coat weight, thickness and moisture levels in paper, pulp, tissue, corrugated line and other converting products are crucial components to the manufacturing process. Out of tolerance moisture levels create wasted product, increased energy usage, downtime and more. Improved product quality and productivity in processing lines through proper moisture control, creating substantial cost savings.

Maintaining the ideal coat weight, thickness, moisture in the production line can mean the difference between a quality product you provide your customers or wasted effort and material. Many basic properties of paper are greatly affected by its moisture content. Its dimensions, flatness, conductivity, strength and fold are among the more significant properties influenced by its moisture content.

Where Is Ideal to Install in the Process?

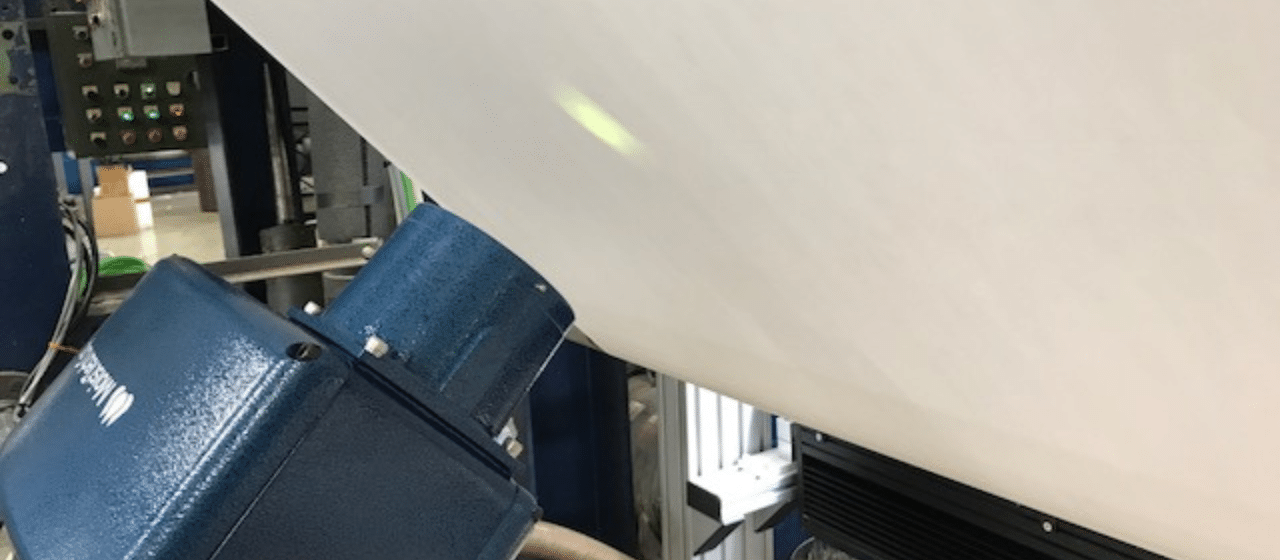

The IR3000C series sensor is an on-line, instant, non-contact moisture reading system that is can be installed in many configurations using the bracket on the back or top of the sensor enclosure. Most typical installations are mounted 4 – 16” (inches) from the product flow to be precisely measured. Changes in product flow can be compensated for by using our filtering, damping and averaging.

-

- After coating station applying water based coatings, either on paper or film

- To measure organic coating coat weight, install after the dryer

- In the case of hot melt or polymer, after extrusion

- Moisturizing unites e.g. LAS, steam curtains before and after chill rolls

- Exit and inlet dryer moisture and temperature

- Moisture profile measurement and correction e.g. before steam profilers, before and after water jet micro sprays, before and after segmented infrared drying

MoistTech Advantages Stand Above the Rest:

product loss software capability

large intense quartz halogen light source

optical system that is several times more efficient than competitors

high speed motor - 100's of more measurements per second

zero ambient or other light effect

no effect from dust, temperature or humidity

display in % wet of % dry weight

rugged industrial design

measure coat weight, thickness, moisture in one

sensor features

Users can enjoy many features of MoistTech’s IR-3000C sensor that can immediately benefit the production line. Measuring any combination of coat weight, thickness, moisture, the technology is unsurpassed. Easy to use and incorporate into many existing systems, we are proud to offer the following features with our IR-3000C series sensors:

pre-calibrated to your application without calibration drifting

optical window contamination alarm/monitor

insensitive to ambient temperatures & lights

store up to 50 different product codes/calibrations

windows operating software for management & control

3 x 4-20mA outputs available

0-10V available

sapphire, kel-F, & Quartz sensor window options

optional explosion proof enclosure

proper measurement

With out of tolerance moisture levels, wasted product is created, increased energy usage, downtime and increased start up times. The processing lines can see improved product quality and increased productivity with proper moisture monitoring, creating substantial cost savings. Users can maintain the ideal moisture, thickness or coat weight in the production line can mean the difference between a quality product to provide your customers or wasted effort and material. Many basic properties of paper are greatly affected by its moisture content: paper dimensions, flatness, conductivity, strength and fold are among the more significant properties influenced by moisture control.

Thousands of MoistTech analyzers are installed not only for the measurement of moisture, but also for other applications such as measuring and controlling: coating thickness, resin content, glue and plastic film thickness and many other constituents – all with one sensor!

The online moisture transmitter can be in a stand alone or multi-sensor configuration.

benefits

product quality monitoring

Allows immediate production line adjustments to improve product quality & consistency

process optimization

Allows 100% monitoring of the production process to reduce product that is “out of specification”

fuel consumption savings

Reduce the energy usage as the drying / cooking process can be controlled by the moistue sensor, resulting in a reduction of energy consumption

low cost - immediate return on investment

highest accuracy utilizing near-infrared technology

easy installation & one-time calibration

newest technology & software updates

very low to zero maintenance needed

surface mount electronics

more options

food products

Our IR-3000F food product sensor can measure moisture, oil, fat/protein and more to meet all production needs.

coke/coal/sinter products

Specifically designed for the dark mineral industry, the CCS-3000 series can measure moisture in dark materials.

IP-67 rated sensor

Ideal for harsh conditions, the IP-67 rated sensor can withstand wash-downs, and aggressive process applications.