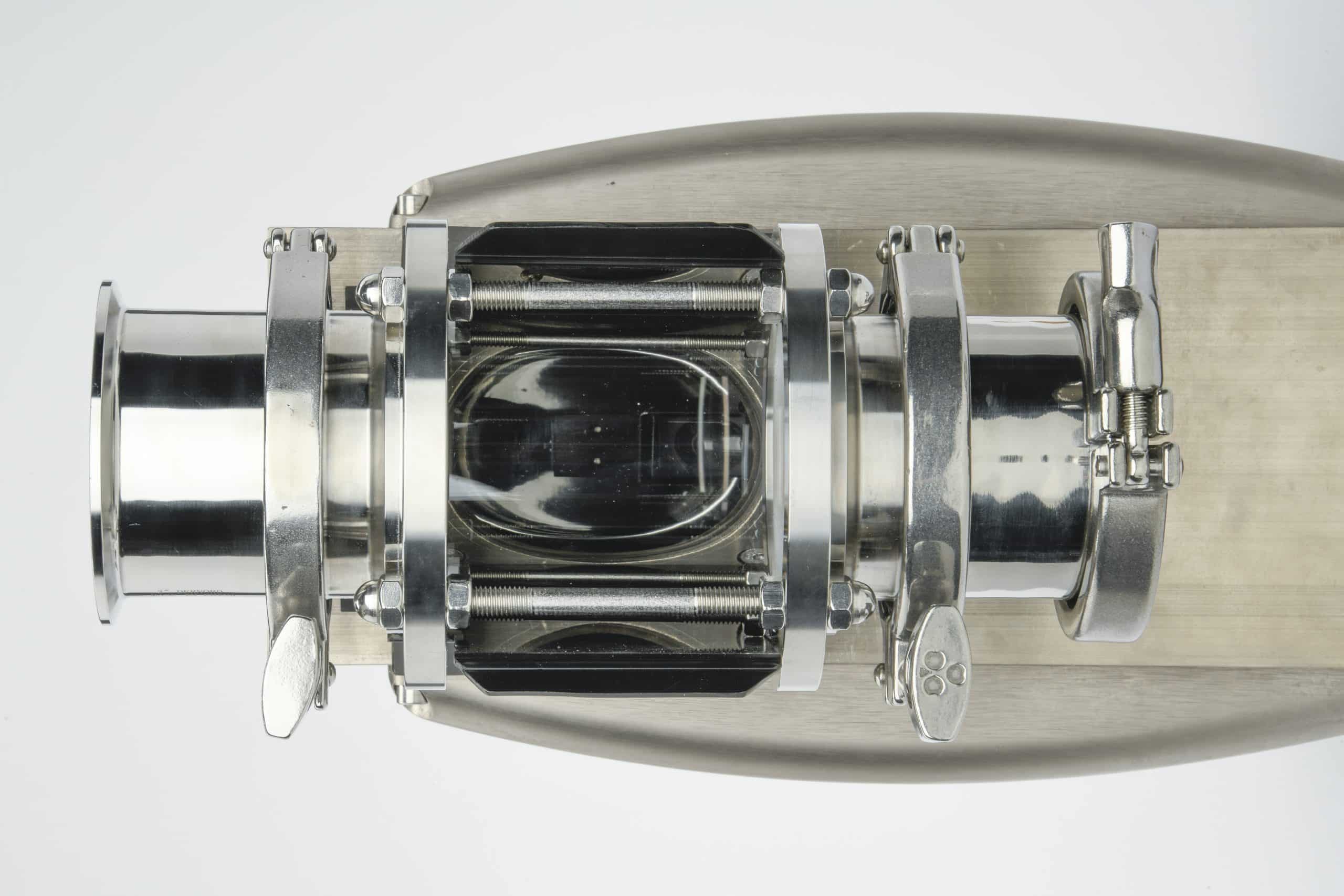

MoistTech has debuted a new product for the food industry that will allow for the moisture content measurement of applications such as soft cheeses, chocolate, sauces, condiments and more! The ability to quickly and efficiently monitor moisture content in these types of food applications is normally very time consuming. But with an instant, in-process ability to measure the moisture content, manufacturers can now seamlessly tie the Food Grade Sanitary Valve Connection directly into their pipeline for instant data monitoring.

Performance & Stability

Requiring an instant method of moisture detection during the manufacturing process is very common in the food industry, but what about when it comes to applications such as condiments, chocolate, soft cheese, sauces and more? Maintaining product integrity and quality is forefront for food manufacturing. Controlling waste, downtime and energy usage help to create process control and increase plant efficiency with automation from moisture control. Allowing personnel to monitor the product line 100% can help to deter common problems seen within the production line and allow focus to solely be on operational improvements and uninterrupted production. Just as with all of MoistTech’s other product line, the Near-Infrared technology is used for measurement along with its ability to connect into the PLC system for full control.

Designed to provide accuracy and repeatability, the MoistTech NIR technology is a ratio-based measurement with prime beam; this eliminates sensitivity due to distance, improves stability and accuracy. The technology captures hundreds of detailed, accurate measurements per second. The ability to pre-set the measurement rate to match the production rate is available on the technology and because there are no routine re-calibrations, this technology is low to zero maintenance which makes it an ideal solution for the manufacturing process.

Installing Instant ROI

The sensors are designed to be installed directly into the pipeline and allow product to flow through the sanitary valve connectoion while monitoring moisture content. The connection allows product to be pushed through the pipeline while having NIR measurements taken through the glass.

Insensitive to material variations such as particle size, material height & color, our moisture sensors provide continuous, reliable readings with zero maintenance and a one-time calibration with a non-drift optical design allowing operational personnel to confidently make immediate process adjustments based on real-time measurements.

Utilizing NIR Technology, which is a state-of-the-art, fast, non-destructive method of measuring and controlling moisture content, MoistTech is able to deliver multiple benefits to its clients – ranging from product quality monitoring, increased plant efficiency, lower energy costs and less waste, to precise dryer control, lower costs and higher accuracy. Instant ROI, low-to-zero maintenance and process optimization can also all be achieved through a MoistTech solution.

Discover the Effect of NIR Moisture Control

If you’d like to learn more about how MoistTech can help with moisture measurement in sugar production, contact us today. We’d be happy to discuss our products and technologies with you and answer any questions you may have.