Return on Investment

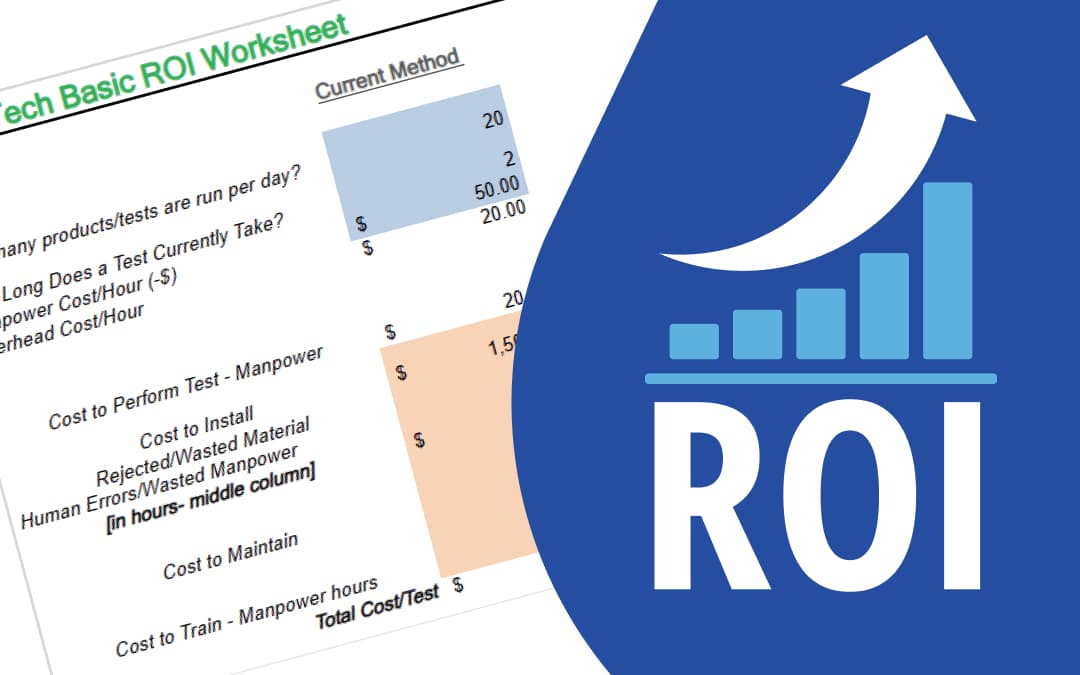

Thinking about a MoistTech system, but not sure about the return on investment compared to your current system? This page gives an overview of prospective ROI improvement and increased profitability when installing a MoistTech system. Every situation is different and some of the criteria may not apply to your application.

MoistTech Saves Money on Labor

MoistTech offers efficiency, low maintenance, and a user-friendly design. All these factors help save money and increase your ROI. For example, if you manually run 20 moisture measurement tests per day, it could take up to two minutes to complete per test. With MoistTech, 20 tests only take five seconds. It can cost $20/hr in labor for an employee to run tests with a current system and only eight cents for a MoistTech system. Normally, a manual test run by an employee takes up not only their time, but it also creates potential issues on the production line while test results are obtained in a manual drying process. Because MoistTech is easy to use, you will not have to spend extensive amounts of time and money training new employees on the system.

Lower Installation and Maintenance Costs

Other moisture sensor systems can cost around $1,500 for installation. MoistTech’s plug-and-play setup makes the installation process simple and comes with step-by-step directions that can be completed in minutes, which saves you time and money. You can also reduce wasted labor hours resulting from human errors as MoistTech’s online unit is automated and connected back to a PC or PLC for ease of use. Say goodbye to maintenance costs after switching systems. MoistTech’s no-drift design never needs to be recalibrated or sent out for maintenance.

Return on Investment Bottom Line

Your current method could cost you an average of $1,620 per test compared to MoistTech’s online sensor costing a little over $5. That adds up to $32,400 for a full day on the current system, where MoistTech would run about $100 for a day. This is a $32,300 saving each day. The cost of a MoistTech unit varies by model, but the $16,000 model will be used for this calculation. If used as a maintenance budget item, the MoistTech unit would have a low monthly cost of around $1,333. The net savings per day of the MoistTech unit compared to your current method would be around $33,632 with a yearly saving of $8,744,233. How many days does it take to recoup the cost of the MoistTech unit? It would take less than one full production day to recoup the cost. By not installing a MoistTech sensor, you could be wasting around $24,000 each day.

Other MoistTech Benefits

Not only does MoistTech save you money, but there are plenty of other benefits. It offers increased speed to the production process, increased plant efficiency, lower rejected and wasted products, lower energy usage, and controlled dryer usage. In addition, the unit is non-contact, offers instant measurements with incredible accuracy, requires no calibration, and features placement versatility.

Contact MoistTech for a Quote Today

If you are ready to save money and improve your production line, contact MoistTech today for a quote.