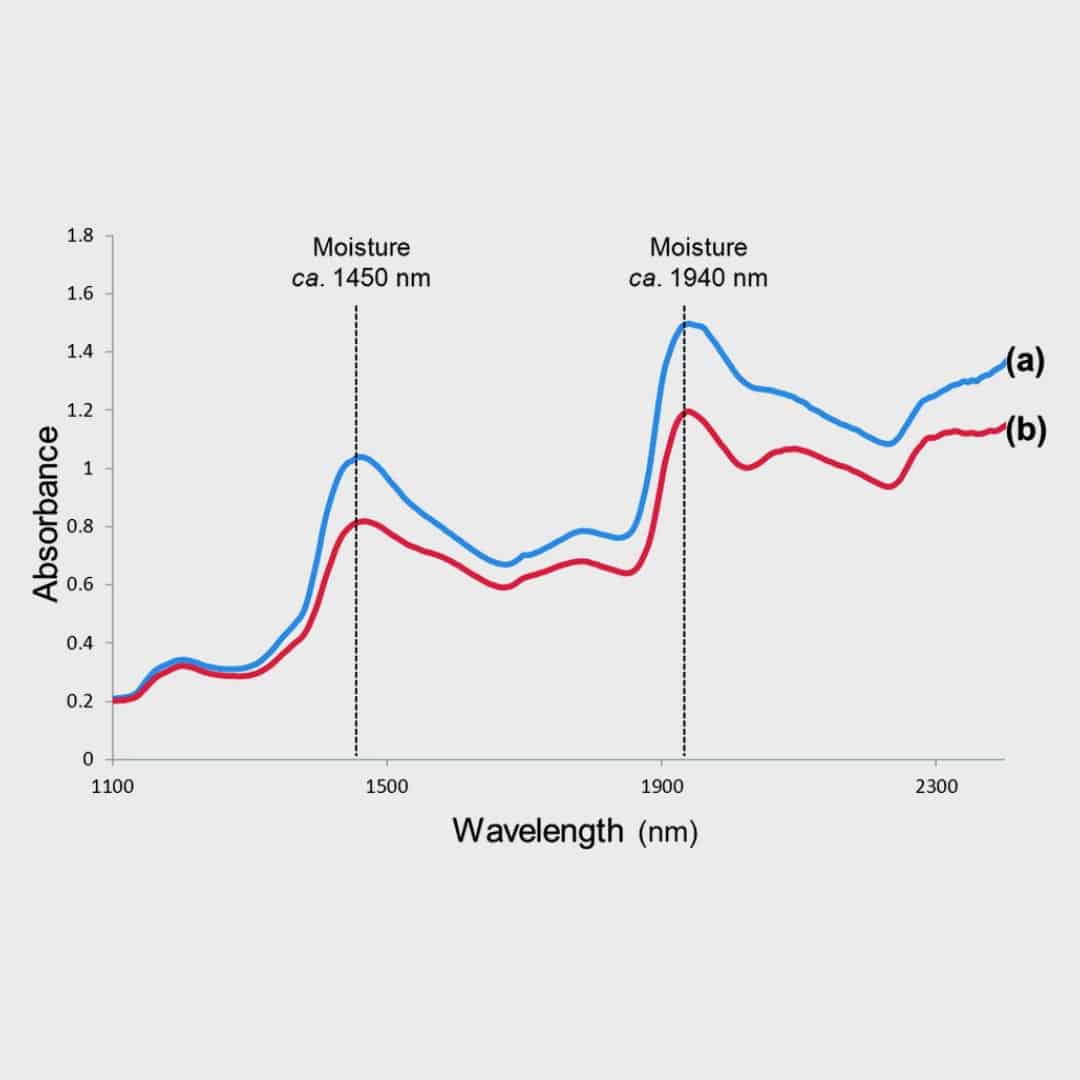

NIR Technology

At MoistTech Corp., we utilize only the best technology for your manufacturing needs. Near-Infrared Technology (NIR) allows for a non-contact solution for accurate moisture content readings. This technology is insensitive to variations like particle size, material height, and color. These sensors only require a one-time calibration to enable personnel to make real-time line adjustments based on measurement readings. This technology, present in our sensors, is best suited for quality control to optimize the manufacturing process, saving your company both time and money. Our IR-3000 sensors can be used throughout the whole paper process —including the initial wet paper pulp stage — measuring a variety of moisture content; this includes water and solvent-based coatings, coat weight thickness and adhesives, and even detecting loss of coatings or spot defects continuously.

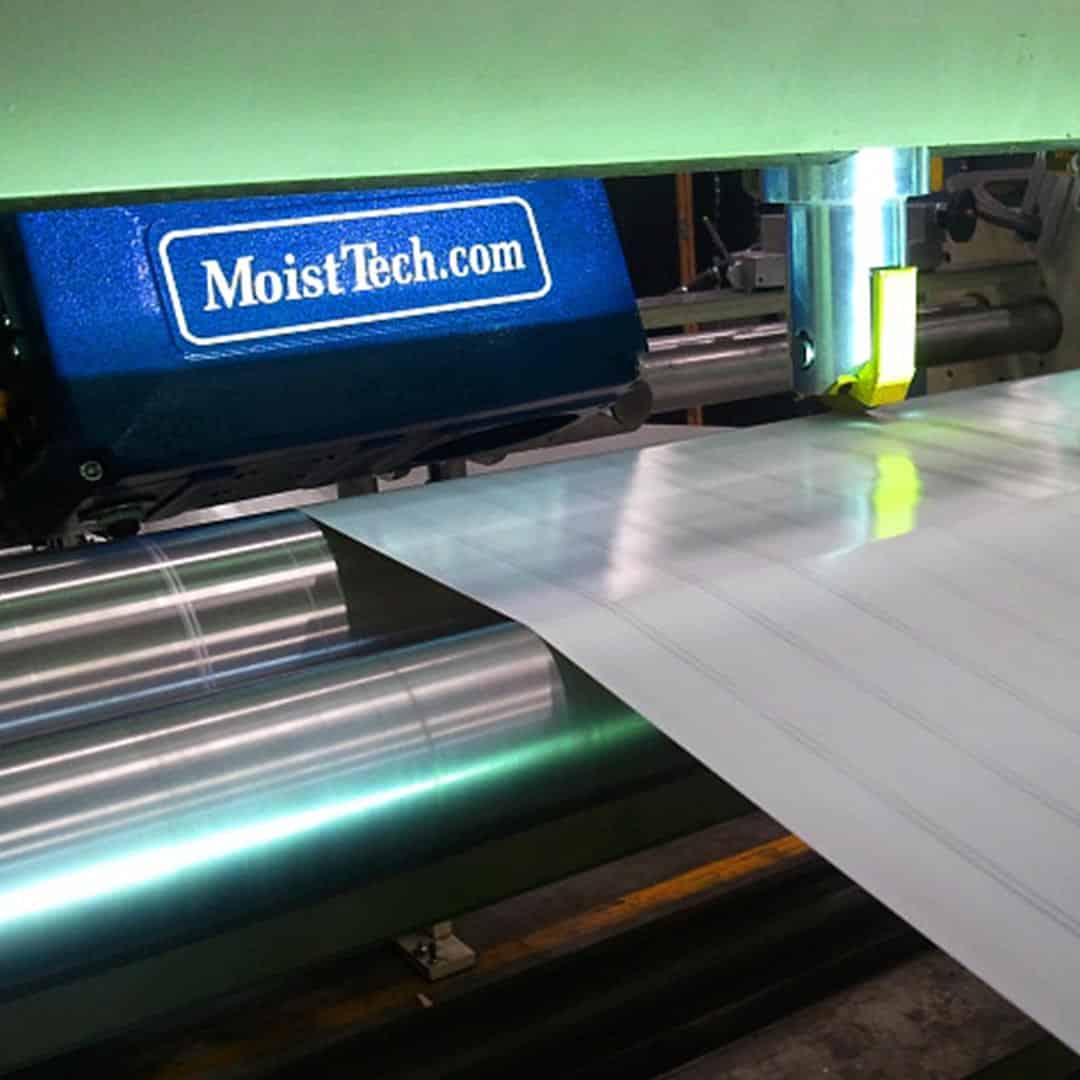

Installation of Moisture Sensors

Our NIR sensors can be installed onto any hopper, silo, material line, belt, or screw conveyor. Results are displayed onto an external display or PC for moisture control and detection.

Benefits Of NIR Moisture Sensors

After the installation of MoistTech Corp moisture sensors, you will see both instant improvements in product production and quality. Other immediate benefits include:

- Lower waste & energy costs

- Process optimization

- Increased plant efficiency

- Dryer control

- Reduced downtime

Continuous Advancements

MoistTech Corp. has over 40 years of experience with NIR technology in a variety of industries with a proven track record for success. Discover the positive effects of NIR Moisture Control. Get your quote today!